Proses ini disebut juga proses "pengeboran minyak". Biasanya pake rig (tempat untuk mensupport proses pengeboran, dsb).Simpel nya, kita membuat lubang di tempat yang diidentifikasi ada kemungkinan sumber minyak/gas di tempat tersebut. Perlu di ketahui dalam proses ini ada kemungkinan blow out (pressure yang tidak bisa di kontrol, langsung ke surface), jadi harus ada pengendalian pressure dari dalam tanah. Pressure downhole / dalam tanah lebih besar dari pressure atmosferik, untuk mengimbanginya biasanya pake mud a.k.a lumpur dengan spesific gravity (berat jenis) tertentu. Mud ini akan menciptakan Hydrostatic pressure yang bisa menahan pressure dari dalam. Setelah "lubang" siap, maka selanjutnya akan di cek apakah ada kandungan minyak/ gas nya.

Peralatan dan proses harus memenuhi:

-High pressures, typical ratings 2000 thru 15,000 psi

-High temperatures, typical rating 250 to 350 degree’s

-Errosion, due to sand & abrasive materials in the produced fluid.

-Corrosion, due to atmosphere and corrosive well fluid.

|

| This is a typical land drilling rig with the necessary supporting facilities. |

RIG TYPE:

THE JACK-UP DRILLING RIG

During exploration drilling the jack-up is floated to location and then its legs are jacked down to the sea bed. Continued extension of the legs raises the deck clear of the waves.

an actual jack up drilling rig

THE SEMI-SUBMERSIBLE DRILLING RIG

The semi-submersible drilling rig is self propelled to its location. Its pontoons are flooded to lower its draft and make it more stable during drilling. It maintains location by anchors.

THE DRILL SHIP

Typically used in deep water. The ship is generally dynamically positioned by computer controlled thrusters (no Anchors)

Note: that deck space is very limited when compared against a semi-submersible.

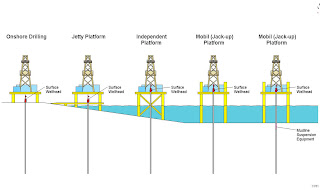

PRODUCTION PLATFORM

-Permanent structure

-Steel or concrete construction

-BOP and wellhead at deck level

-Contains multiple wells

-Deviated drilling is used to reach all areas of the reservoir.

an actual jack up production platform

During the drilling process the well is controlled by a blowout preventer stack and choke manifold.

As the well is drilled each annulus is sealed off by the wellhead.

After the tubing is installed the blowout preventers are removed.

A series of valves and flow control devices known as the Xmas Tree are installed to control the flow from the well.

Finally the drilling rig is removed.

Function of wellhead :

1.Penyangga casing string

2.Tempat terpasang alat pengontrol aliran

1. Wellhead atau kepala sumur pengeboran adalah alat yang digunakan pada saat pengeboran yang berfungsi untuk tempat menggantungkan pipa selubung (casing)

FUNGSI

Alat untuk menggantungkan rangkaian casing (pipa selubung) yang dipakai dalam suatu sumur pengeboran minyak dan gas

Alat untuk menggantungkan rangkaian casing (pipa selubung) yang dipakai dalam suatu sumur pengeboran minyak dan gasMerupakan suatu susunan rangkaian spool flanges, casing hangers dan valves.

Alat untuk tempat mendudukan blow-out

Material : low alloy carbon steel forging

Temperature rating :

Tekanan Kerja : > 10,000 psi

Panjang : +/- 60 inchi

Diameter wellhead : 13-5/8”

Berat total assembly : +/- 1 ton

WELLHEAD CASING HEAD HOUSING

WELLHEAD CASING SPOOL

2. X-tree atau kepala sumur produksi adalah alat yang di pasang di atas wellhead setelah pemboran selesai yang berfungsi untuk mengontrol aliran fluida produksi (gas, minyak atau air) agar sumur dapat di produksi dengan aman.

UKURAN: Mempunyai ukuran size dan pressure (tekanan)

CONTOH: X-Mas Treee 3” x 2” with pressure (tekanan) disesuaikan dengan besarnya tekanan lapisan suatu sumur bot 2000 psi, 5000 psi sampe 10,000 psi.

MERUPAKAN RANGKUMAN BEBERAPA VALVES, FITTING DAN CHOKES

- Material : low alloy carbon steel forging

- Temperature rating :

- Tekanan Kerja : 6,500 Psi

- Panjang : +/- 80 inchi

- Berat total assembly : +/- 1 ton

BLOWOUT PREVENTION

If the mud fails to control the pressure, oil and gas begins coming to the surface during the drilling process, We call this a kick.

If action is not taken then the well fluids will begin coming out of the hole in an uncontrolled manner, We call this a blowout

Blowout Preventers (BOP’s) are our final safety barrier during drilling and are used to control kick’s & prevent blowouts.

# RAM TYPE BLOWOUT PREVENTER

# ANNULAR TYPE BLOWOUT PREVENTER

Sealing on variable size & shapes of pipes & tools

Closing on open hole

Stripping pipe

Steel bits may be faced with tungsten carbide or polycrystalline diamond, depending on the type of rock being cut.

Comments

Post a Comment